Originally posted on sawmillcreek.org

I started my PBB last night. As some of you may know, I recently

purchased a used PBB system hardware from a forum member. I wanted to

make a nice, functional PBB so I could begin my woodworking hobby.

I looked at many of the designs posted on the forum and decided that I like the one that Paul Greathouse designed the most.

http://www.sawmillcreek.org/showthread.php?t=86069Unfortunately, the pieces I received were not long enough to make a

bench exactly the same size, so I improvised. Perhap latter after I

have gotten used to the system I will add longer extrusions.

I drew up the project using Alibre Design at 48"x24". The side rails are 3" and the end pieces are 6" deep.

I made all the cuts the EZ way except for the notch in the end piece. I used a Jig saw there.

Bill

I used a Kreg pocket hole jig to make all the joints. I like the Kreg system because it is fast and usually pretty accurate.

All of the pieces are 3" wide and made of 3/4" plywood. The cross members are spaced every 4.5"

Howard Miller Posted:

Howard Miller Posted:I use the Kreg also. It is good and easy.

Trent Flemming Posted:

Looks like your off to a great start. Keep the pictures coming and welcome to the fold.

Trent

Bill Griggs Continued:The rest of the cross members

I got the rest of the cross members in place and then realized I had to take two out because I used the wrong piece. This was easy with pocket screws. Glue and dadoes would have been a whole other sad story

.

I got this straightened around.

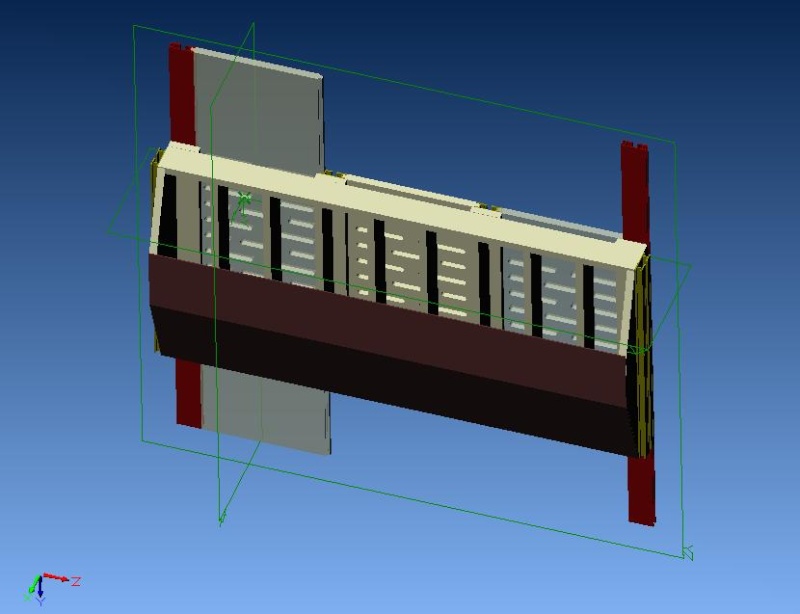

SME plates.

SME plates.

Next I attached the SME base plates to the cross members with pocket screw. The base plates are at right angles to the cross members and may be hard to see. 24"x3".

Possible layout.

Possible layout.

I put the rails and sme on the table without screwing anything together. Any last minute recommendations would be appreciated before I finish up.

Michael Parr Posted:

Michael Parr Posted:Got any pictures of the final piece. I was wondering if you put a bottom on this or left it open. I like this kind of design since I saw this link (

http://www.blumtool.com/pages/benchhorse.html) and like they use bench clamps to clamp pieces to the side of the table. Putting Holes in the side to accommodate pipe clamps would not be hard but was wondering how the bottom was done. I personally would not like adding a permanent vice to the table as I need to store it against the garage walls to get a car in.

Paul Greathouse Posted:Darn, that sure look familiar.

Your doing a great job Bill, you will be very happy with the design you chose. I really like not having to worry about the sawdust piling up on the tabletop.

If you decide to hook up dust collection to the bottom let us know how well it functions. I originally intended to have bottom dust collection for mine but I haven't done it yet. I just slide open the table top panels and vacuum it out when necessary.

Mike Goetzke Posted:Bill - nice bench. Looks like you are having too much fun. When I built mine I wish I had a Pbb to build my PBB

.

As far as dust goes, I have solid modules on the top of my bench and noticed I've been getting more and more dust shoot out the back especially at the end of the cut. I thinks it's because the kerf in my table top has widened due to the modules moving left/right slightly. I'm wondering if the slotted table my help eliminate this problem.

Mike

Paul Greathouse Replied:Mike

I'm not sure if its the open design that does it or if my dust collection gets to take the credit. I have an older Makita with factory dust collection similar to a Hilti 267E. My kerf is wide also due to the tops moving a little. I would rather have them loose and easy to move, rather than tight and hard to move. The only dust shoot-out that I get is at the very end of the cut. Ironically it blows onto the top of my dust deputy and shop vac.

Bill Griggs Replied:Got any pictures of the final piece. I was wondering if you put a bottom on this or left it open. I like this kind of design since I saw this link (http://www.blumtool.com/pages/benchhorse.html) and like they use bench clamps to clamp pieces to the side of the table.I am still working on it. The build is in progress at last.

I like the bench horse idea.

Bill

Burt Waddell Posted:Bill,

That is looking good. I've always admired the top on Paul's PBB.

Burt

Bill Griggs Continued:More work done.Got side tracked building sets for a school play with My EZ Smart rails and so Never got to finish my PBB.

Anyway I got a chance to work on the PBB some more this week. I got out my Kreg jig and made some legs for the bench using plywood I ripped on the EZ Rail.

After I got the legs attached to the base I realized that the PBB woulb be too heavy to move easily so I added some 4" Locking, Casters I got for $5.50 on an ebay store (SES Casters).

I was pleasantly surprised to find that I managed to get the table level in both directions without trying

!!! I think the accurracy of the EZ Smart cuts and the accuracy of the Kreg joints did the trick.

Once I had the table done it was a quick process to install the SME and Edison bridge.

Pay no attention to the partially finished Joes CNC 4x4 Hybrid router table in the background.

Tomorrow night I will cut the Plywood panels for the SME using my new PBB for the first time. After that I will make the bottom covers and add a dust collection port.

Bill

Dino Makropoulus Posted:

Dino Makropoulus Posted:Bill. It must be the first time where

(A) we're starting with a simple rail to

(B) build the table that

(C) builds the final componets to put the simple rail in top to

(D) make a complete tool system that can do it all.

Then, we can take the rail off and

( E) have a portable system that can do it all again.

Very-very confusing to start thinking ez.

Wecome to eurekazone.

Give us some input and pictures for your hybrid CNC.

Give us some input and pictures for your hybrid CNC.

Bill Griggs Replied:

I think you just said a mouth full. I would have never tackled a

project like this with a table saw because I am afraid of it. The sheets of plywood are too large to hold steady while I rip the pieces to size. As you can see I am cramped for space until I finish the storage cabinets (which is part of the reason I bought the EZ Smart rails in the first place)..... It is nice to have a tool that can make a tool.

The hybrid is a great set of plans. I highly recommend folks take a look at the joescnc website to get some ideas.

The base of the table was built in less than one week using the plans. I believe I will be finished before June is over.

The plans give the parts needed and where to buy them the cheapest. They also list a link to the members only website which has logs of over 60 machines currently under construction or completed.

I would tell more but I am not sure what the rules about this are here on the creek.

Bill

Dino Makropoulus Replied:

Dino Makropoulus Replied:

Bill,

This is eurekazone and we love to learn easy ways.

The CNC is the future and your ideas are welcomed.

Thanks.

Bill Griggs Replied:I had 2 PM messages asking about the CNC Router so I think the information might be of genera interest. I got the plans from

http://www.joescnc.com. There is also lots of information available on cnczone.com. I will make a posting in the CNC part of the sawmillcreek forumn so that folks here can share in the CNC experience.

Moderator, If I shouldn't post links please let me know and I will remove them.

Bill

First use of PBB

I got a late start tonight so I got less accomplished than I hoped. I decided to make the sliding panels for the SME. Originally I planned to cut rabbits on both sides of the board but then I decided to make one deep rabbit on one side so that the plywood was slightly higher than the SME. Hopefully this would prevent me from cutting slots through the SME rails. I won't know till I get done if this was a good idea. I still need to cut slots in the top of the board.

Anyway the saw dust on the table means things are getting used.

One thing I need to do is come up with a way to keep the fence square to the rail. This is the weak point of the design in my opinion.

Bill

Plywood flus or raised?

If anyone knows a reason why the plywood shouldn't be higher than the top of the SME please speak up before I make the other two.

Burt Waddell Replied:Bill,

I tried the approach you are using and didn't like it. It made taking advantage of the clamping capabilities of the SME's more difficult. Think about how you will use the SME.

I was trying to accomplish the same thing - didn't want to cut the SME. I've finally given in to the fact that cutting the SME is the best way

to go.

Burt

Joseph N. Myers replied: Bill,

I agree with Burt about cutting into the SME's. It doesn't really hurt

any of the functions of the bridge/clamping and if you get too many

cuts in the SME's(i.e., too wide), just flip the SME's around (i.e.,

front to back).

One of the other problems with worrying about cutting into the SME's is

that you would really have to be very "extremely" careful about setting

the depth of cut each time the thickness of the wood changes (as I do

often).

And I like others welcome you to the wonderful world of Eurekazone.

Regards, Joe

Bill Griggs Replied:

Thanks for the advice Burt. Could you please explain some of the problems with clamping so that all may learn?

Bill

Burt Waddell Replied:Bill,

The projection of the wood above the SME means that you aren't working

on a flat surface. Holding an item by clamping it to one of the out

side rails doesn't work. As you try to tighten the clamp, the other

side or end is lifted off the table. It can be done by balancing the

pressure and using two clamps.

When you try to clamp when the board is going across two modules, The

board cannot be pulled into contact with the SME. If you do pull the

wood until it contacts the sme both ends are in the air.

I also tried to use a modified miter gauge with this setup. The wood projecting up got in the way and it was impossible.

To me the benefits were to few for the cost.

Burt

Bill Griggs Replied:

After reading the advice of others I have changed my mind and my PBB to

make the panels flush with the SME. Guess what? It works better as

promised.

Now I need to machine all the slots into the table top. I also plan to

make a few panels which have bench dog holes on them similar to another

table on the market. Also I want to make a panel which has SME mounted

on it to make a pseudo Kreg jig table for pocket screw joints.

Too many ideas and not enough time. I have to put in some molding this weekend for the better half's satisfaction.

Bill