| | An idea for converting the ez rail in an eurorail |  |

|

+5Mike Goetzke DinoTheCarpenter Burt Bruce Benjamin Andres Cuevas 9 posters |

|

| Author | Message |

|---|

Andres Cuevas

Posts : 40

Join date : 2008-07-02

Age : 48

Location : Santiago, Chile

|  Subject: An idea for converting the ez rail in an eurorail Subject: An idea for converting the ez rail in an eurorail  July 10th 2008, 9:27 pm July 10th 2008, 9:27 pm | |

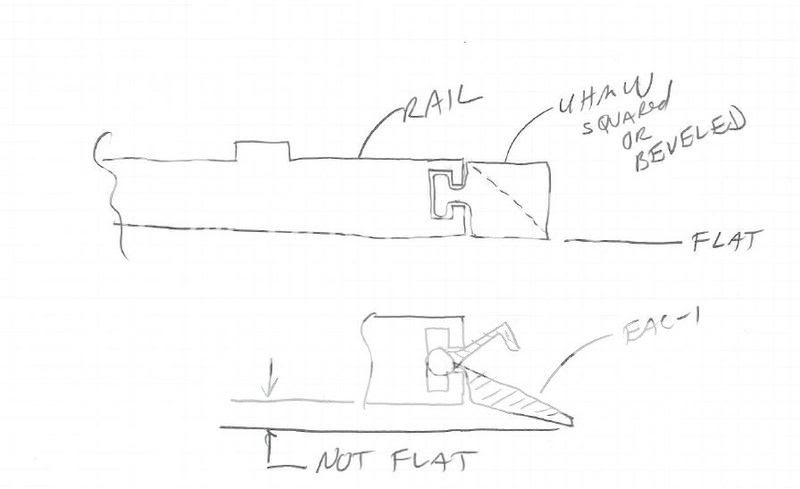

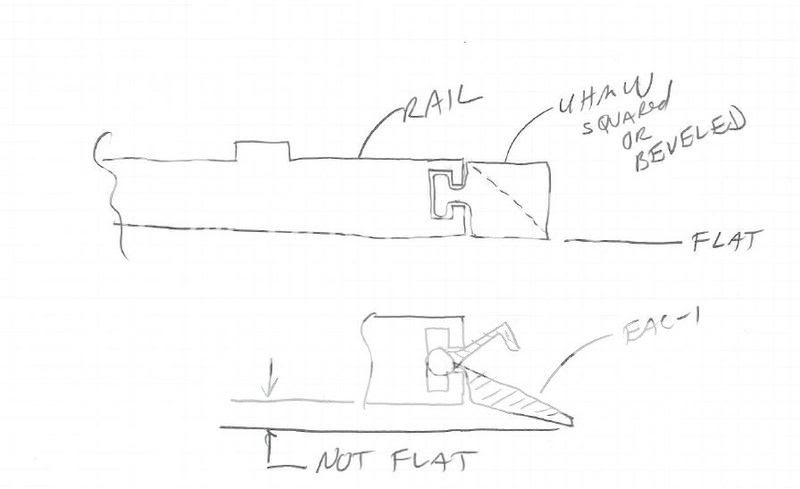

| I'm working in an idea for cutting with my Hilti in the rail without the ez base. I want to do that for some cuts I have to make, I need more than 5 cm of depth cut capacity. This is what I have in mind:    I'm thinking in making this with a piece of wood, but any material can be used, even aluminum, Dino? With this I don't have antichip protection in the right side of the blade, but I can use the ACE-1 without using the ez base. I'm not worried about the antichip in the right side of the blade for the cuts I have to make because are edge jointing. What I think it's important is the joint between the rail and the adapter, no play must be there. And the adapter must have the same thickness of the rail. Andres. | |

|

| |

Bruce Benjamin

Posts : 97

Join date : 2008-07-01

Age : 61

Location : Redding, California (Far Northern Ca.)

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 10th 2008, 9:44 pm July 10th 2008, 9:44 pm | |

| This looks like a pretty good idea, Andres. You pointed out the potential problems with making sure it all fits right. I have a, "Keyhole" bit that I've used to make my own track slots for my router table and drill press table fences but I'm not sure if it cuts the right dimensions for the EAC-1. It might but I have to measure. If it doesn't fit I'm not sure how one would go about making a perfect fit slot. I have the feeling that my bit might cut a little too wide. I believe Dino has a Euro-style rail in the works for just this purpose but I don't think it's happening soon. The problem with that rail is that it might not be of any use if you want to use a non-Euro saw on the rails. And all of the regular rails we have wouldn't match up with the new Euro rails. Having Dino make the adapter insert like you showed in Sketchup would be a great idea, I think. It wouldn't be cheap but it would be fairly straight forward for him to have some rail inserts made from either aluminum or from UHMW that would fit perfectly. Anti-chip protection for the right side of the blade might be accomplished with some sort of insert or strip that would attach to the bottom of the saw. I'd have to look at mine to find out what would work but it doesn't seem impossible. I'm not going to check right now because it's way over 100 degrees outside and the air is so full of smoke and ashes from all of our forest fires around Redding, Ca. that I don't even want to be in my garage/shop.  I tried to spend a little time out there earlier today but my eyes were burning from the smoke and I was drenched with sweat in just a few minutes. It should cool off to about 85 or 90 by 10:00 PM at least.  Thank God for those hard working fire fighters. Bruce | |

|

| |

Burt

Posts : 86

Join date : 2008-06-23

Age : 77

Location : Sumter, SC

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 10th 2008, 9:58 pm July 10th 2008, 9:58 pm | |

| Andres,

That looks like you are on the right track to come up with a good solution. For the right side protection use a piece of UHMW or plywood - much like the AC-3 that Dino uses for left side saws.

Burt | |

|

| |

DinoTheCarpenter

Posts : 67

Join date : 2008-06-16

Location : Edison NJ

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 10th 2008, 10:33 pm July 10th 2008, 10:33 pm | |

| Nice idea Andres.

With ez, anything can be done.

I will make the first one for you and ship it with your order.

Fax me a drawning with exact dimentions.

I don't have the Hilti or the Festool saw anymore.

Not sure if the Worx saw haves the same offset with Festool and Hillti. | |

|

| |

Mike Goetzke

Posts : 40

Join date : 2008-07-01

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 12:05 am July 11th 2008, 12:05 am | |

| Andres - nice idea for your saw. If you use (I mean if Dino makes it out of) UHMW why cut a groove for the anti-chip - just trim the UHMW and use it as the anti-chip. Maybe this is a good sub for the anti-chip even when using the Smartbase. | |

|

| |

Dik Harrison

Posts : 233

Join date : 2008-07-01

Age : 76

Location : Evans, GA, USA

|  Subject: I agree Subject: I agree  July 11th 2008, 7:36 am July 11th 2008, 7:36 am | |

| I have thought of doing this for my Worx. But I agree with Mike, just using UHMW in the edge slot and trimming it with the saw, should give you anti-chip protection. If you add a strip of UHMW to your base outside the blade, you have anti-chip on both sides. | |

|

| |

DinoTheCarpenter

Posts : 67

Join date : 2008-06-16

Location : Edison NJ

|  Subject: We make the task ezier. Subject: We make the task ezier.  July 11th 2008, 7:44 am July 11th 2008, 7:44 am | |

| - Mike Goetzke wrote:

- Andres - nice idea for your saw. If you use (I mean if Dino makes it out of) UHMW why cut a groove for the anti-chip - just trim the UHMW and use it as the anti-chip. Maybe this is a good sub for the anti-chip even when using the Smartbase.

If the task is to make it ez. We make the task ezier. Mike, You and Andres just invented the new dual ez/ euro rail. I will call the extruder today and see if we can use the tooling for something else. Thanks.

Last edited by DinoTheCarpenter on July 12th 2008, 6:55 am; edited 1 time in total | |

|

| |

Mike Goetzke

Posts : 40

Join date : 2008-07-01

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 8:52 am July 11th 2008, 8:52 am | |

| - DinoTheCarpenter wrote:

- Mike Goetzke wrote:

- Andres - nice idea for your saw. If you use (I mean if Dino makes it out of) UHMW why cut a groove for the anti-chip - just trim the UHMW and use it as the anti-chip. Maybe this is a good sub for the anti-chip even when using the Smartbase.

If the task is to make it ez. We make the task ezier.

Mike,

You and Andres just invented the new dual ez/ euro rail.

I will call the extruder today and see if we can use the tooloing

for something else.

Thanks. Dino/All, I also had this idea last night when I saw this post. When working on my PBB I have a dedicated rail. I never use pencil marks when using my PBB - I use a tape measure or some type of scale. On the PBB why not have a piece of UHMW that spans both sides of the blade but doesn't interfere with the rail. This would eliminate the need for the anti-chip on the rail and allow the rail to lay flat at all time....a "Traveling Anti-Chip." Mike | |

|

| |

Bruce Benjamin

Posts : 97

Join date : 2008-07-01

Age : 61

Location : Redding, California (Far Northern Ca.)

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 3:08 pm July 11th 2008, 3:08 pm | |

| The only problem I see with using UHMW as the left side anti-chip is that if you change blades you need to change the whole thing. If you use the EAC-1, (Like a regular rail) you can change it when you change blades. The Euro-rail extension made from UHMW may be easier but I don't see it as being very cost effective if you change blades. My vote is for the way Andres first pictured it, with a removable/replaceable EAC-1.

Bruce | |

|

| |

Robert Fordham

Posts : 11

Join date : 2008-07-02

Location : Westchester, New York

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 4:19 pm July 11th 2008, 4:19 pm | |

| Another down to UHMW on both sides of the blade is you loose the edge to line up the cut. When using my PBB I measure and mark with a pencil, put the keeper under the rail until I can barely see the line and cut. | |

|

| |

Andres Cuevas

Posts : 40

Join date : 2008-07-02

Age : 48

Location : Santiago, Chile

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 4:39 pm July 11th 2008, 4:39 pm | |

| - Bruce Benjamin wrote:

- The only problem I see with using UHMW as the left side anti-chip is that if you change blades you need to change the whole thing. If you use the EAC-1, (Like a regular rail) you can change it when you change blades. The Euro-rail extension made from UHMW may be easier but I don't see it as being very cost effective if you change blades. My vote is for the way Andres first pictured it, with a removable/replaceable EAC-1.

Bruce I was thinking the same thing. It could be more work to make the groove for the EAC-1, but then it's easier to just change the EAC-1. For different blades and different angles it's easier with the EAC-1. | |

|

| |

Mike Goetzke

Posts : 40

Join date : 2008-07-01

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 5:06 pm July 11th 2008, 5:06 pm | |

| - Bruce Benjamin wrote:

- The only problem I see with using UHMW as the left side anti-chip is that if you change blades you need to change the whole thing. Dino has a design with a slot for the fasteners that attach the UHMW block - allowes you to renew/move the UHMW. If you use the EAC-1, (Like a regular rail) you can change it when you change blades. The Euro-rail extension made from UHMW may be easier but I don't see it as being very cost effective if you change blades. If you look at Dino's site, I think the cost would be a wash. My vote is for the way Andres first pictured it, with a removable/replaceable EAC-1.

Bruce I just think sometimes less is more (less pieces that is). Mike | |

|

| |

DinoTheCarpenter

Posts : 67

Join date : 2008-06-16

Location : Edison NJ

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 5:09 pm July 11th 2008, 5:09 pm | |

| hi guys. Andres original idea works good. Use a new aluminum extrusion (1-3/4") wide similar to ez to include a clamping track. Same extrusion can be used for other applications. Andres, Today's order is free. I will refund all your money. It pays to have the smartest guys at the ez team.  I just cut the sides of one track (1-3/4") use doublesided tape and the job was done. I like to make the new extrusion slidable to the ez rail as per Andres design and include a clamping track. Having the clamping track at the end we can use the smart clamps for narrow pieces. | |

|

| |

Bruce Benjamin

Posts : 97

Join date : 2008-07-01

Age : 61

Location : Redding, California (Far Northern Ca.)

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 5:30 pm July 11th 2008, 5:30 pm | |

| - Mike Goetzke wrote:

- Bruce Benjamin wrote:

- The only problem I see with using UHMW as the left side anti-chip is that if you change blades you need to change the whole thing. Dino has a design with a slot for the fasteners that attach the UHMW block - allowes you to renew/move the UHMW. If you use the EAC-1, (Like a regular rail) you can change it when you change blades. The Euro-rail extension made from UHMW may be easier but I don't see it as being very cost effective if you change blades. If you look at Dino's site, I think the cost would be a wash. My vote is for the way Andres first pictured it, with a removable/replaceable EAC-1.

Bruce

I just think sometimes less is more (less pieces that is).

Mike I'm sorry Mike, I don't quite get what you mean when you say, "Dino has a design with a slot for the fasteners that attach the UHMW block.- allows you to renew/move the UHMW." What fasteners? If you're talking about removing and replacing the UHMW when it gets chewed up or when you want to change blades then I think that the original EAC-1 strips will be much cheaper than UHMW. If that's not what you're talking about then I'm  Bruce | |

|

| |

Andres Cuevas

Posts : 40

Join date : 2008-07-02

Age : 48

Location : Santiago, Chile

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 5:51 pm July 11th 2008, 5:51 pm | |

| - DinoTheCarpenter wrote:

- hi guys.

Andres original idea works good.

Use a new aluminum extrusion (1-3/4") wide similar to ez to include a clamping track. Same extrusion can be used for other applications.

Andres,

Today's order is free. I will refund all your money.

It pays to have the smartest guys at the ez team.

I just cut the sides of one track (1-3/4") use doublesided tape and the job was done. I like to make the new extrusion slidable to the ez rail as per Andres design and include a clamping track.

Having the clamping track at the end we can use the smart clamps for narrow pieces. Dino, do you still need the measures of the Hilti saw? I'm in home now, so can give it to you. BTW: Thanks for the free order.  | |

|

| |

DinoTheCarpenter

Posts : 67

Join date : 2008-06-16

Location : Edison NJ

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 11th 2008, 6:02 pm July 11th 2008, 6:02 pm | |

| - Andres Cuevas wrote:

- DinoTheCarpenter wrote:

- hi guys.

Andres original idea works good.

Use a new aluminum extrusion (1-3/4") wide similar to ez to include a clamping track. Same extrusion can be used for other applications.

Andres,

Today's order is free. I will refund all your money.

It pays to have the smartest guys at the ez team.

I just cut the sides of one track (1-3/4") use doublesided tape and the job was done. I like to make the new extrusion slidable to the ez rail as per Andres design and include a clamping track.

Having the clamping track at the end we can use the smart clamps for narrow pieces.

Dino, do you still need the measures of the Hilti saw?

I'm in home now, so can give it to you.

BTW: Thanks for the free order.  Andres, I got it from Burt. Thanks for the idea. Enjoy the weekend. | |

|

| |

GEHAGEMAN

Posts : 3

Join date : 2008-07-02

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 12th 2008, 1:56 am July 12th 2008, 1:56 am | |

| Dino, put me in line for the Euro extrusions | |

|

| |

Burt

Posts : 86

Join date : 2008-06-23

Age : 77

Location : Sumter, SC

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  July 12th 2008, 10:12 am July 12th 2008, 10:12 am | |

| - Dik Harrison wrote:

- I have thought of doing this for my Worx. But I agree with Mike, just using UHMW in the edge slot and trimming it with the saw, should give you anti-chip protection. If you add a strip of UHMW to your base outside the blade, you have anti-chip on both sides.

Dik, The Hilti and Festool saws are approx the same distance from the slot in the base to the blade. The Worx is entirely different. On the Hilti/Festool you need add about 1 3/4". On the worx you need to only add about 5/8". I think that you could probably just add a couple of layers of UHMW tape to one of the regular white or grey inseert and be all set. There would be a problem adding the amount it would take with a Festool or Hilti. Burt | |

|

| |

Mike Goetzke

Posts : 40

Join date : 2008-07-01

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  August 12th 2008, 9:06 am August 12th 2008, 9:06 am | |

| - DinoTheCarpenter wrote:

- Nice idea Andres.

With ez, anything can be done.

I will make the first one for you and ship it with your order.

Fax me a drawning with exact dimentions.

I don't have the Hilti or the Festool saw anymore.

Not sure if the Worx saw haves the same offset with Festool and Hillti. Dino - Just my luck, on many occasions I have a rip cut that I'm making using the rip fence that leaves the cut off only under the anti-chip. If the anti-chip were made from UHMW like the variation I suggested to Andres invention I think the solid UHMW antichip could support the thin cutoff better than the flexible anti-chip??? (sorry for the poor sketch)  Mike | |

|

| |

DinoTheCarpenter

Posts : 67

Join date : 2008-06-16

Location : Edison NJ

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  August 12th 2008, 9:48 am August 12th 2008, 9:48 am | |

| - Mike Goetzke wrote:

- DinoTheCarpenter wrote:

- Nice idea Andres.

With ez, anything can be done.

I will make the first one for you and ship it with your order.

Fax me a drawning with exact dimentions.

I don't have the Hilti or the Festool saw anymore.

Not sure if the Worx saw haves the same offset with Festool and Hillti.

Dino - Just my luck, on many occasions I have a rip cut that I'm making using the rip fence that leaves the cut off only under the anti-chip. If the anti-chip were made from UHMW like the variation I suggested to Andres invention I think the solid UHMW antichip could support the thin cutoff better than the flexible anti-chip???

(sorry for the poor sketch)

Mike Mike, The new edges are fine. Do you have the white or the light gray edges? Going solid $$$ we may have other problems. Thanks | |

|

| |

Mike Goetzke

Posts : 40

Join date : 2008-07-01

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  August 12th 2008, 9:53 am August 12th 2008, 9:53 am | |

| - DinoTheCarpenter wrote:

Mike,

The new edges are fine. Do you have the white or the light gray edges?

Going solid $$$ we may have other problems.

Thanks Just my luck I bought many extra white edges when I got my rails  . Mike | |

|

| |

DinoTheCarpenter

Posts : 67

Join date : 2008-06-16

Location : Edison NJ

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  August 12th 2008, 11:52 am August 12th 2008, 11:52 am | |

| - Mike Goetzke wrote:

- DinoTheCarpenter wrote:

Mike,

The new edges are fine. Do you have the white or the light gray edges?

Going solid $$$ we may have other problems.

Thanks

Just my luck I bought many extra white edges when I got my rails  . .

Mike I can use them if you don't. I like the white edges better... For my applications. | |

|

| |

Mike Goetzke

Posts : 40

Join date : 2008-07-01

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  August 12th 2008, 4:34 pm August 12th 2008, 4:34 pm | |

| - DinoTheCarpenter wrote:

I can use them if you don't.

I like the white edges better... For my applications. As usual thanks for the generous offer but I find my slightly chipped up anti-chip works as well as a new one (maybe because I've mostly been milling hardwoods). I'm actually on the originals. | |

|

| |

Bruce Benjamin

Posts : 97

Join date : 2008-07-01

Age : 61

Location : Redding, California (Far Northern Ca.)

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  August 12th 2008, 5:24 pm August 12th 2008, 5:24 pm | |

| Mike, this is what I was trying to explain to you back when you, uh, well, lost it. The new EAC-1 edges are flat. The UHMW edges are unnecessary for this purpose. Where the UHMW edges would be useful was from Andres's original plan to extend the edges for use with a saw with a, "Euro-style groove" in the base, such as the Hilti 267. Add the new EAC-1 to the outside of the UHMW and it will work fine.

Bruce | |

|

| |

Mike Goetzke

Posts : 40

Join date : 2008-07-01

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  August 12th 2008, 11:48 pm August 12th 2008, 11:48 pm | |

| - DinoTheCarpenter wrote:

Mike,

The new edges are fine. Do you have the white or the light gray edges?

Going solid $$$ we may have other problems.

Thanks Dino - please post a photo of the new gray edge for me. Thanks | |

|

| |

Sponsored content

|  Subject: Re: An idea for converting the ez rail in an eurorail Subject: Re: An idea for converting the ez rail in an eurorail  | |

| |

|

| |

| | An idea for converting the ez rail in an eurorail |  |

|