This thread was originally posted on SMC by Joseph N. Myers. It is here with his

permission.There have been some recent threads/posts on the best way to make sure the Rip Fence is parallel to the EAC-1 (white/gray edge) especially if the EAC-1 is not completely straight. (Or in my case, with the Makita 5008MGA, the EAC-1 is chipped).

One way around this problem is to come up with an alignment tool that ignores the EAC-1 and uses the center slot on the Guide Rail (aka, Bridge) and of course, the CS w/ base. The bottom line will be something that looks like a "C" with the top going against the center slot and the bottom against the Rip Fence.

I have a bunch of boards to rip to the width of 1-9/16 so now seem to be a good time to make this tool. I took the prototype piece and placed it under the Bridge. I installed the rip fence, placed it tightly against the prototype and tighten the knobs. To help place the prototype, I moved the CS in front of the prototype and butted it against the saw blade.

(My Rip Fence is made out of plexiglass so it doesn't show up very well in the following picture).

I then removed the prototype and placed a board in its place to double check the width. Worked fine.

I had a board laying around that was 5/8" that I used to make the alignment tool (AT). With the Rip Fence (RF) still in place, placed the board against the RF and proceeded to make 3 cuts, the bottom, middle and top. Screwed the pieces together and now have an AT.

Now when I want boards ripped to 1-9/16, just put the AT at one end of the RF, tighten the knob, other end of the RF, etc., etc. And of course, I'll need a different AT for the different sizes I'll need. I may consider making an adjustable AT but for now, no big deal making

other sizes.

BTW, way too late for me tonight so I hope that above makes sense! If not, feel free to ask questions. And of course, you may have your own requirement/design ... this one happens to work for me for now!

Regards, Joe

Ed Brady Posted:Joe,

Good post. I responded to the problems thread re chip out on the EAC1, but could not remember that you posted similar problems. I also suggested to Dino that using the SRK for fence alignment works well, but requires extra steps to disassemble/reconfigure. I plan to make an adjustable alignment tool that runs on the rail, but it seems like a lightweight device would be a good accessory for EZ to offer.

EDB

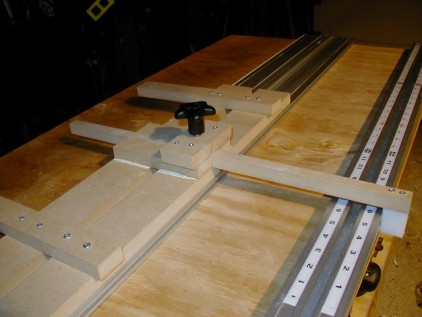

Robert Fordham Posted:Home made story stick

I made this when I only had the basic 100 system. I needed numerous 3 inch wide strips of 1/4 plywood. This allowed accurate repeat cuts with just smart clamps, and made the job faster and EZier.

The sled rides the rail. The story stick arm is adjustable, and the 5 star knob locks it into place. The white block at the end of the arm is UHMW. This allow me to get 2 edges parallel, and allows repeat cuts. Down side is you need to remove it each time you make a cut.