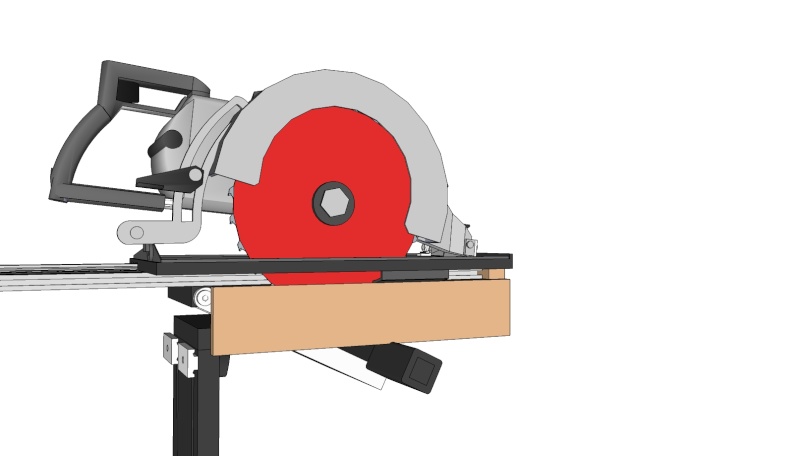

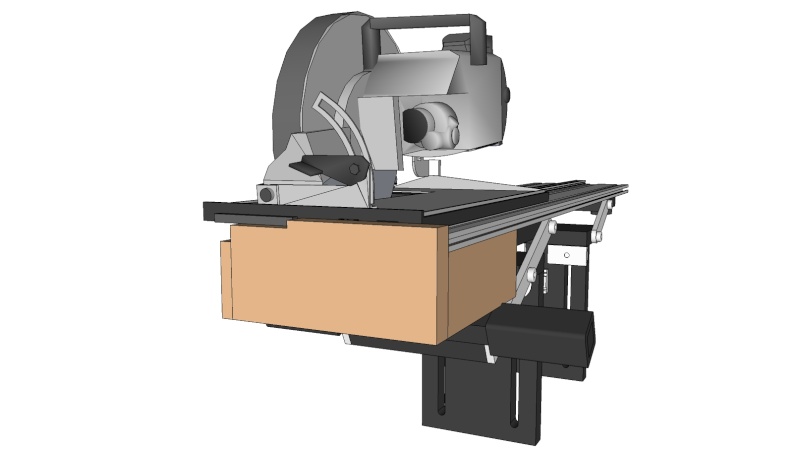

his thread was originally posted on SMC.My WORX doesn't have a brake, so the blade is still spinning when I want to raise the bridge for the next cut. I have to be careful, but am afraid that someday I might forget, so I designed a blade guard for the bridge. Here are some drawings, I'll post pics when I get it built.

Randal Stevens Posted:

Randal Stevens Posted:Excellent idea. Also well worth it for those left handed worm saws.

Dik Harrison Posted:The finished article

Here are the pics of the blade guard.

First is the top view, the core is three layers of 3/4" ply, and the guard and front are poplar.

This is the bottom, the knobs clear the hinge arms, handle, cross piece, and bridge.

Here the blade is lowered to cut 1 1/2" stock. Note the cord I use to raise and/or keep raised the saw's blade guard. Since I now have this guard, I'll probably keep the guard raised when the saw is on the rail.

The other side, I probably should make a guard on that side for when I cut in the other direction. I haven't done so yet, so I may never add that guard. I might also put a guard on the other end of the rail, but it will have to be of a different design. Note that the Smart Base hits the end block to prevent the saw from being pushed too far.

Here you can see the saw kerf from the top.

Mike Goetzke Posted:Dik - Nice design. Looks like you run your saw on the "unconventional" side of the rail? Do you always run your saw to the stop? When I had a Worx saw I tore up the white anti-chip a couple of times lifting the saw too quickly. Running the saw to a stop would prevent damaging the anti-chip in the working area. With a brake on the saw now I usually release the trigger as soon as I'm through the cut. This seems to reduce the dust explosion you get when the blade breaks through the cut.

Mike

Dik Harrison replied:Thanks Mike,

...Looks like you run your saw on the "unconventional" side of the rail? I always keep the keeper piece under the rail and use my Biesemeyer fence for measurement most of the time (rarely use a cut line and the EAC-1), so I cur on the "unconventional" side.

...Do you always run your saw to the stop? My squaring stops are on the side that I cut toward, so I always run the saw to the end of the rail.

...When I had a Worx saw I tore up the white anti-chip a couple of times lifting the saw too quickly. Running the saw to a stop would prevent damaging the anti-chip in the working area. I too have chewed up a few EACs by lifting the saw before the blade has stopped. Maybe someday I'll break down and get a saw with a brake.

...With a brake on the saw now I usually release the trigger as soon as

I'm through the cut. This seems to reduce the dust explosion you get

when the blade breaks through the cut. Speaking of the Biesemeyer fence, I just ordered a Wixey Digital fence gadget, I'm tired of converting my digital caliper readings to fractions to set the fence when I'm cutting small pieces.

Andres Cuevas Posted:Nice work Dik!!!

What I did with my bridge was cut the EAC-1, this way I don't have anti-chip protection in the parking area of the bridge, now the blade guard is always closed in both ends of the bridge.

Andres.